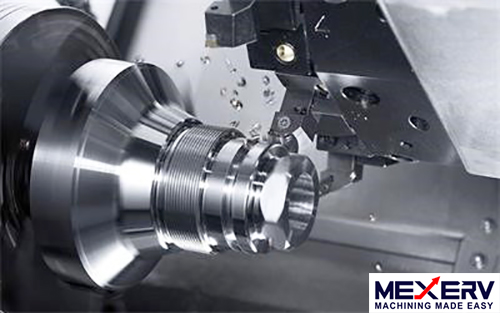

Cnc Turning

Computer numerical control (CNC) turning is a subtractive process where a cutting tool is placed against a spinning piece to take material off. This is usually done with a CNC lathe or turning center which cuts the material including wood, metal, and plastic. Generally it can perform drilling, milling and lathe operations.

A computer numerical control (CNC) system consists of three basic components: A CNC software that is a set of instructions, a machine control unit which governs the mechanical and electrical components, and processing equipment, also called machine tool.

- Flexible and Versatile.

- High production efficiency.

- Reduces the labor intensity of the operator.

- High machining accuracy.

- It can process complex shapes.

Specifications

| DESCRIPTION | UNIT | Spec |

|---|---|---|

| CAPACITY | ||

| Swing Over bed | mm | 510 |

| Chuck dia. Max | mm | 210 | 254 |

| Max. Turning dia | mm | 320 |

| Max. Turning Length | mm | 310 | 480 |

| Admit Between Centres | mm | 440 | 610 |

| SPINDLE | ||

| Spindle nose | type | A2-6 |

| Hole through spindle | mm | 61 | 77 |

| Spindle speed | rpm | 3500 |

| Spindle motor power | kW | '9/11 | '11/15 |

| FEED | ||

| Inclination of Carriage | Deg | 30° to Horizontal Plane |

| Travel X - Axis | mm | 185 |

| Travel Z - Axis | m/min | 370 | 560 |

| Rapid traverse (X/Z) - Axes | m/min | 30 / 36 |

| TURRET | ||

| No. of stations | nos. | 8 |

| Tool shank size | mm | 25 x 25 |

| Max. Boring bar dia | mm | 40 |

| Turret Indexing | type | Hydraulic |

| Turret indexing time | sec | 0.8 to 1 |

| TAILSTOCK | ||

| Quill dia | mm | 75 | 85 |

| Quill stroke | mm | 100 |

| Quill taper | Type | MT-4 | MT -5 |

| CNC SYSTEM | ||

| Controller | Type | Fanuc / Siemens* |

| MACHINE SIZE | ||

| L x B x H | mm | 2065 x 1925 x 1680 | 2505 x 1650 x 1920 |

| Weight | Kg | 3500 | 3800 |

Features of CNC milling

- Flexible and Versatile

- High machining accuracy.

- High production efficiency.

- It can process complex shapes.

- Reduces the labor intensity of the operator.